Check Valves

If a fluid gets contaminated while flowing in its channel, backflow of this fluid can contaminate its source. For this reason, backflow of fluids should be prevented to avoid contamination. Check valves are specifically designed to allow fluids to pass only in one direction, so that there is no backflow in an industrial system. Two-way check valves are the most commonly used types of check valves in industries. In some cases, check valves having vents are used as three-way check valves, which protect fresh fluid supply at the source from getting contaminated in case a backflow of contaminated water takes place. These devices have atmospheric vents, which redirect contaminated water to a designated drain. Check valves are available in different sizes and shapes – the ideal shape and size of check valves to be used depends on the requirement.

Check valves manufactured by Brosco prevent backflow successfully and are resistant to high pressure and temperatures.

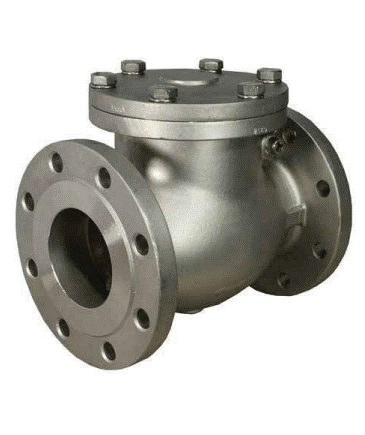

Check Valves | Casting

Steel-cast check valves are used to control the flow of liquid, ensuring that they flow in the same direction. This way, back flow of the fluid is easily prevented. Cast steel check valves are used in industries such as pharmaceuticals, gas and diesel circuits, and oil.

We offer premium steel-cast check valves to prevent backflow and ensure resilience to high temperatures and pressures.

Product Details

- Manufacturing Range

- Specific Features

1) Size: 2″ NB to 16″ NB

2) Class: 150#, 300#, 600#

3) Materials: WCB, LCB, CF8, CF8M, CF3, CF3M

• Swing Type Disc

• Suitable for the horizontal & vertical pipe runs.

• Bolted Cover.

• All parts are accessible from the top for easy servicing.

• Hard faced (Stellite-6) seating surfaces also available.

• The design offers a low-pressure drop operation,

which makes the valve more energy efficient.

| P. NO. | ITEM . | QTY | MATERIAL |

|---|---|---|---|

1 | BODY | 1 | ASTM A 216 Gr. WCB |

C.I. TO IS 210 Gr. FG 220 | |||

ASTM A 351 Gr.CF8/CF8M/CN7M | |||

2 | COVER PLATE | 1 | ASTM A 216 Gr. WCB |

C.I. TO IS 210 Gr. FG 220 | |||

ASTM A 351 Gr.CF8/CF8M/CN7M | |||

3 | DISC | 1 | C.S. WITH 13% Cr. FACING |

S.S.316/S.S.304 | |||

TEFLON COATING OPTION | |||

5 | SEAT RING | 1 | C.S. WITH 13% Cr. FACING |

Integral Seat For Alloy Steel Valve | |||

AISI 304/AISI 316 | |||

5 | DISC HINGE | 1 | ASTM A 216 Gr. WCB |

C.I. TO IS 210 Gr. FG 220 | |||

ASTM A 351 Gr.CF8/CF8M/CN7M | |||

6 | STUD & NUT | Req. | ASTM A 193 Gr. B7 |

ASTM A 194 Gr. 2H | |||

7 | COVER GASKET | 1 | SPIRAL WOUND SS 304 WITH CAF |

Standards :

| 1 | 2 |

|---|---|

Design Standard | BS 1868 / API 6D / ASME B16.34 |

Inspection & Testing Standard | API 598 / BS 1868 / BS 6755 |

Face to Face | ASME B16.10 |

Flange Connection | ASME B16.5 |

Butt Weld Connection | ASME B16.25 |

Pressure Temperature Rating | ASME B16.34 |

| NB | ASA-150 | ASA-300 | ASA-600 | |||

|---|---|---|---|---|---|---|

L | H | L | H | L.5 | H | |

40 | 165 | 138 | 241 | 159 | 241 | 175 |

50 | 203 | 152 | 267 | 176 | 292 | 190 |

65 | 216 | 161 | 292 | 187 | 330 | 200 |

80 | 241 | 173 | 317 | 194 | 356 | 205 |

100 | 292 | 200 | 356 | 275 | 432 | 229 |

150 | 355 | 247 | 445 | 284 | 558 | 311 |

200 | 495 | 284 | 533 | 331 | 660 | 375 |

250 | 622 | 327 | 622 | 368 | 787 | 378 |

300 | 698 | 353 | 711 | 400 | 838 | 435 |

350 | 787 | 461 | 812 | 511 | 889 | 565 |

400 | 914 | 498 | 838 | 552 | 990 | 592 |

450 | 914 | 527 | 914 | 581 | 1092 | 642 |

500 | 940 | 581 | 990 | 616 | 1193 | 694 |

600 | 965 | 622 | 1143 | 664 | 1397 | 735 |

Check Valves | Forging

If a fluid gets contaminated while flowing in its channel, backflow of this fluid can contaminate its source. For this reason, backflow of fluids should be prevented to avoid contamination.

Check valves manufactured by Brosco prevent backflow successfully and are resistant to high pressure and temperatures.

Product Details

- Manufacturing Range

- Specific Features

1) Size: ¼” NB to 2″ NB

2) Class: 800#, 1500#

3) Materials: A105, LF2, F5, F11, A182 (F304 / F316)

• Hard faced (Stellite-6) seating surfaces also available

• Horizontal Piston type Integral hard face Seat Design.

• Design appropriate for high-pressure temperature service.

• Two piece self-aligning packing gland.

| P. NO. | ITEM . | QTY | MATERIAL |

|---|---|---|---|

1 | BODY | 1 | A 105 |

A 182 (F 304) | |||

A 182 (F 316) | |||

2 | SEAT RING | 1 | AISI 410 |

AISI 304 | |||

AISI 316 | |||

3 | VALVE | 1 | AISI 410 |

AISI 304 | |||

AISI 316 | |||

5 | GASKET | 1 | SPIRAL WOUND S.S. 304 WITH CAF FILLER |

6 | COVER | 1 | A 105 |

A 182 (F 304) | |||

A 182 (F 316) |

Standards :

| 1 | 2 |

|---|---|

Design Standard | BS 5351 |

Inspection & Testing Standard | API 598 / BS 6755 Part 1 |

Face to Face | ASME B16.11 |

Flange Connection | ASME B20.1 |

Butt Weld Connection | ASME B16.25 |

Pressure Temperature Rating | ASME B16.34 |

| SCREWED / SOCKET WELD | ||

|---|---|---|

SIZE | A | B |

15 | 87 | 61 |

20 | 95 | 67 |

25 | 106 | 67 |

40 | 140 | 95 |

50 | 144 | 110 |

OUR CLIENTS

Customers Have and Things We Do Every Day to Meet Those Needs A positive introduction. We work hard to provide the very best on-boarding experience possible.