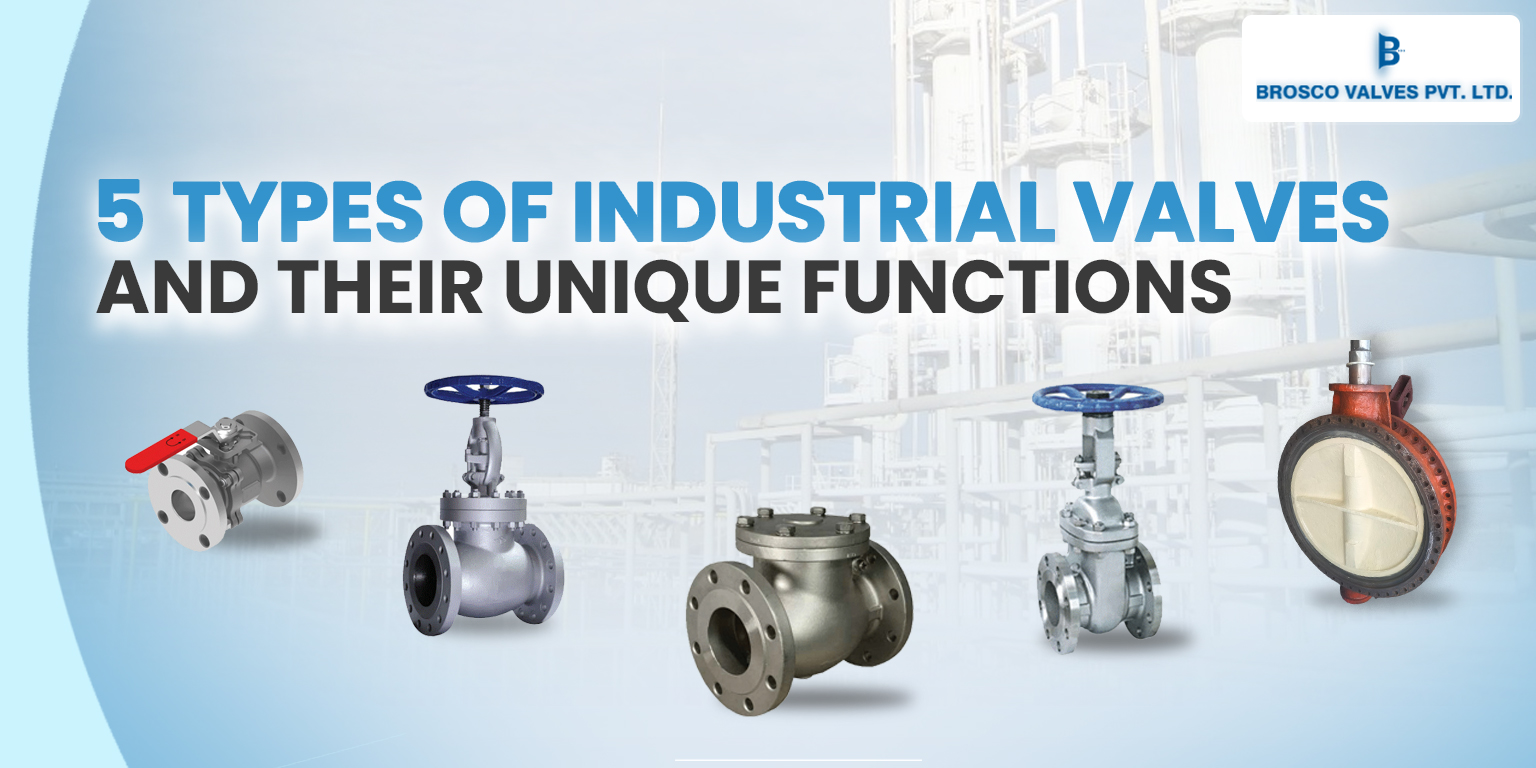

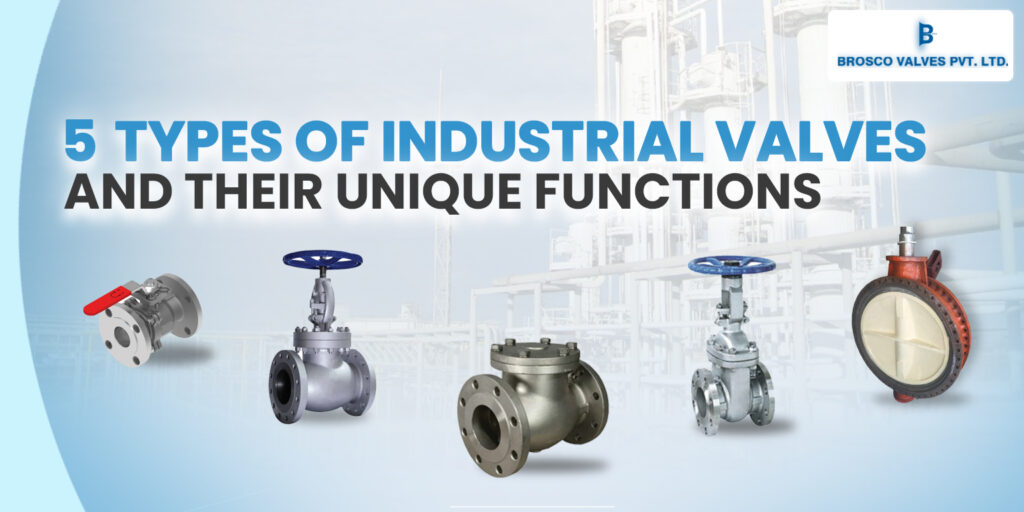

5 Types of Industrial Valves and Their Unique Functions

Safety should be the first priority for factories, which deal with different forms of fluids and gasses in their manufacturing processes. Industrial valves help regulate the flow of these elements and are crucial in factories and manufacturing units in various sectors. Valves are available in different types—what valve to opt for depends on factors such as the industry requirements, the type of fluid or gas whose flow needs to be regulated, and the factory’s budget.

Ball Valves

With a rotating ball and a shaft controlling the passage of fluids and gasses, a ball valve is light, compact, and affordable. So, it is an excellent option for relatively small requirements in industries like oil and gas, food and beverage, petrochemicals, and automotives. Moreover, premium PVC ball valves are easy to install and durable, reducing installation and maintenance costs for factories.

Globe Valves

These valves consist of a globe-like cavity around the port area, from which they derive their name.

- T-type globe valves, with horizontally placed seats, are particularly good at supporting an actuator over the yoke, as the yoke arms and bonnet threads are unlikely to bend with pressure in this type of globe valve.

- In angle-type globe valves, the ends of the valve are at a right angle. If the flow of a fluid is pulsating, this type of globe valve can best manage such an effect.

- Y-pattern globe valves have minimal flow resistance, and they offer a low pressure drop in comparison to other types of globe valves. Oil and gas and petrochemical companies commonly use Y-pattern globe valves in their factories.

Easy to operate, durable, and leakage-proof, globe valves are commonly used in the food and beverage, oil and gas, offshore, water works, and wastewater operations.

Check Valves

With check valves, fluids can pass only in one direction, which ensures that there’s no backflow in factories. These are bifurcated as two-way and three-way check valves, with two-way check valves being the most commonly used. Lined with atmospheric vents, these valves redirect contaminated water to specific drains. One may find check valves at power plants, oil fields, refineries, chemical plants, industries dealing with wastewater treatment, etc.

Gate Valves

These valves either block fluid flow completely or allow a fluid to pass entirely in a pipeline. So, gate valves are always either fully open or fully closed. A shaft is rotated to open and close the gate. Gate valves are popular in industries wherein the fluid direction fluctuates; for this reason, they are commonly used in the pipeline industry.

Butterfly Valves

Powered by a disk, an actuator, and a rod, butterfly valves are common in HVAC systems, petrochemical operations, ship-building processes, and the oil and gas industry, among others. Since these valves are compact and lightweight, they work exceptionally well for less or medium-flow operations and in manufacturing units with tiny spaces. Broadly, butterfly valves are classified as zero-offset, double-offset, and triple-offset, depending on whether—and at how many levels—the disk of the valve is offset.

The global industrial valve market was valued at USD 72 billion as of 2023. The market for valves is high because of the care and caution that factories need to exercise when dealing with potentially harmful and even lethal fluids and gasses. With a firm foothold in the allied valve manufacturing and maintenance industries, Brosco prides itself as a leading valve manufacturer in India.

We govern our clients’ end-to-end valve selection, installation, and maintenance processes, offering exceptional-quality valves that are durable and sturdy. We would love to understand your requirements and help you install the best-suited valves at your factory. Click here to get in touch with us!